Here are some pretty pictures of the ROTOR (RCK) cranks and an interview with Mike Ponting, who sells and distributes them. For the main article associated with this little slide show you’ll need to visit the health and fitness section at Singletrackworld.com

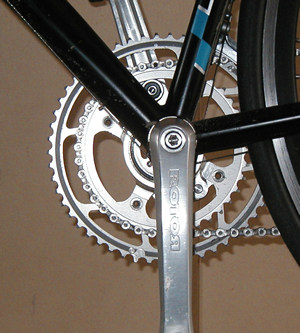

Picture showing the obvious offset design of the RCK.

And from the other side.

Matt asks: When I back-pedal or spin the cranks round when the bike is stationary, I am aware that they do not spin as freely as a conventional crank. Does this friction counter-act the benefits of the offset crank?

Mike answers: No doubt there is more friction as there are more bearings, however, all the direct comparative tests that have been performed i.e. comparing a standard crank set-up with the Rotor RCK have demonstrated that despite this extra friction the performance benefits are still derived. What you may lose in additional friction is easily compensated for by the other benefits.The manufacturer has a policy of constant development and they are working on reducing the additional friction through using improved bearings.

Matt asks: Have you any recent studies and have any of them been published in respected journals?

Mike replies: The studies have not been published in journals as yet, but here I attach details of a study carried out by Dr. Alfredo Cordova Martinez, University of Valladolid, Spain. The only other more recent information I have was published in ‘220 magazine’ and contains some preliminary test information from the British Triathlon Association (BTA) Sports Scientist John Gregory.

John Says: “We aren’t sponsored by ROTOR and we must stress that our findings are preliminary at this stage. However, after two sets of trials it appears the rotor cranks system improves performance.” John’s preliminary research revealed that lactate and oxygen consumption were lower for a given workload than with a conventional system. This was true for power outputs of 150, 200,250 and 300 watts.

Reproduced by kind permission of 220 Triathlon

(Ed. Mike sent me a copy of the Valladolid study as a ‘pdf’ file, but alas I’m not very bright and can’t work out a way to display it. The study is available on the www.rotorbike.com site, but you’ll need a good grasp of the Spanish language if you’re going to glean much from it. This study did indeed suggest lower lactate levels and HR for a given intensity. Whilst I’m butting in, personally I look forward to seeing some independent studies published in established to confirm ROTOR’s benefits – I’m sure these will come. However, I would be very surprised if these cranks aren’t found to be more efficient. The whole thing makes a lot of sense to me).

Matt asks: There are obviously a few more moving parts on this crank compared with a conventional system. How long before they go sloppy?

Mike replies: In short, we don’t know exactly. Rotor (the manufacturer) have made some claims, but we think these are optimistic and without more thorough testing in UK conditions we are unwilling to make any definitive claims. The main bearing on the eccentric plate and the bearings on the pivots are the vulnerable points. The kit needs regular cleaning but must not be sprayed with a power washer (because of pressured water penetrating the bearings). It needs regular lubrication and checking for correct alignment in the BB shell. Like any piece of equipment worked hard in hard conditions some things are going to wear out, but replacement parts are available from the manufacturer. As I mentioned before the manufacturer has a policy of constant development and they are always working on ways to improve longevity, and the ease of maintenance by refining the design.

Matt asks: With all the extra pivot points, is there likely to be more friction when the whole thing is covered in mud from an off-road ride?

Mike replies: With the extra pivots there is more potential for mud sticking to the crank set than with a standard set up, but this does not seem to be a problem. The RCK has been used extensively at Elite level with Pro riders in Spain with a lot of success, and Jodi Vickery has been riding it successfully this year in the Sport Category of the SAMS and NPS in the UK with no problems of clinging mud causing extra drag.

Matt asks: When one crank is at the bottom of the pedal stroke, how offset is the other crank in degrees, compared to a conventional set-up?

Mike replies: No idea – the inventor/designer, Pablo Carrasco, is an aeronautical engineer by training and he studied the problem of the “dead-spot” in pedalling after noticing it when cycling. I know that through the various prototype developments they have altered the angle as a variable, but I can’t tell you what the current angle is, or why they have settled on this position, sorry.

Once again, for the full article you’ll need to visit the health and fitness section at Singletrackworld.com

© Matt Hart. TORQ 2002